Premium Leather from High-Quality Australian Livestock

Compare with composite material, genuine leather is more stretchable, breathable, durable and sustainable, which cannot be replaced by any artificial leathers. Therefore Woolly kids only select the finest material for our products.

Woolly kids selects premium A-Grade genuine leather from Laverton area, all of our raw materials come from high-quality breeding species slaughtered as by-products of the Australian integrated livestock industry, in order to maximize the utilization of every gift from nature. Every cowhide will immediately be sent to experience tannic-acid process which means it is tanned without chrome and any artificial chemical pollution.

Soles Designed for Little Feet

Tailored Comfort and Suppor

We have specially designed soles in distinct materials and functions for children at different stages:

For babies--We use cowhide as the outsole for overall wrapping, and locally apply small pieces of natural rubber to increase slip resistance, maximizing the simulation of barefoot feeling, providing protection for the healthy development of children's feet at the initial stage of walking.

For toddlers--We use retractable elastic heels on most of our collections, which makes these shoes easy to wear and take off. At the same time, the outsole is designed to buckling at one-third, which can take precautions against Flatfoot.

From Leather to Shoes

Meticulous Handcrafting Process

Manual craftsmanship is a key feature of all high-quality shoes. At Woolly Kids, we prioritize quality, ensuring that each pair of shoes is meticulously handmade by our skilled shoemakers. From cutting and stitching to shaping, brushing, and pasting, every step is carried out with utmost care. We firmly believe that manual craftsmanship is a living heritage, surpassing the precision of machinery.

Every pair of woolly kids that you meet will undergo 17 manual shoe-making technical process, from shoe-last making to sole fitting, accumulated with the skills by some of the best artisans in the world. What's more, every shoe last will be repeatedly reshaped to better fit different types of new series and the demand of healthy growth for kids.

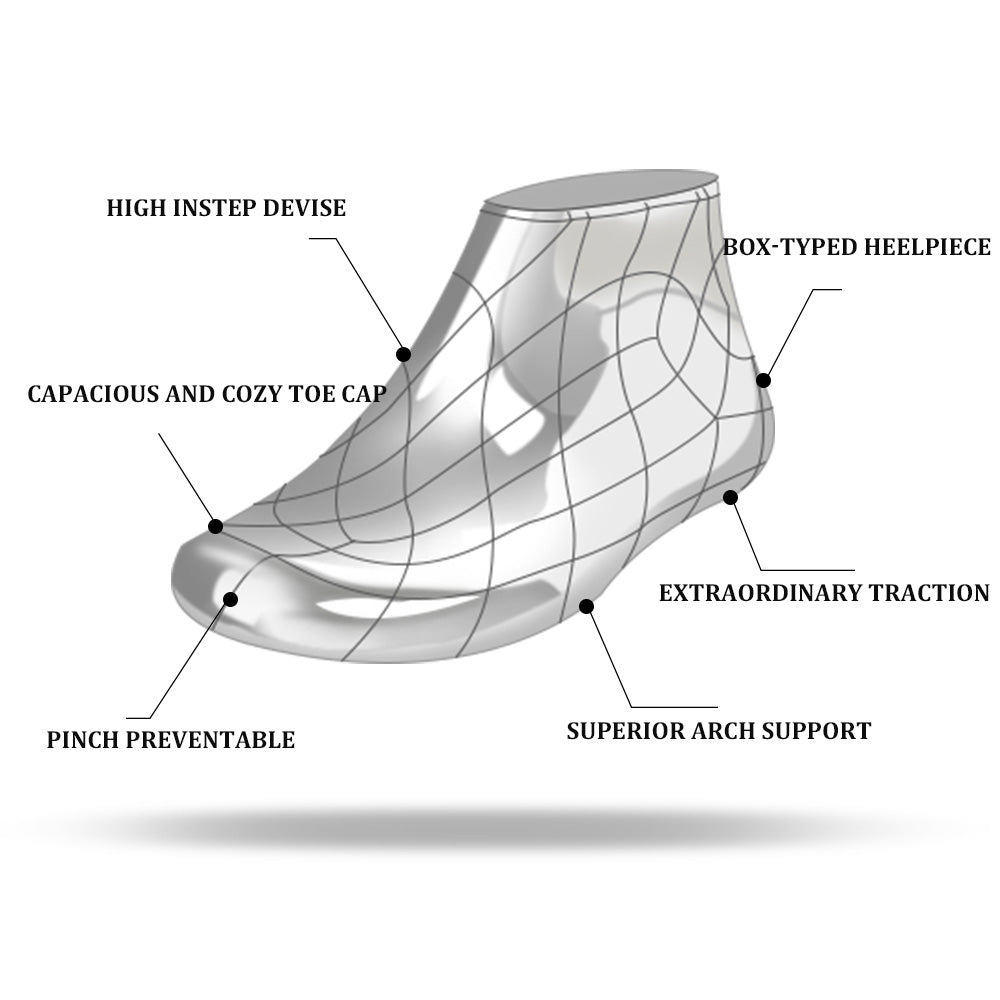

Perfect Fit with Custom Shoe Lasting

Shoe last is a mechanical form that has a shape similar to that of a human foot. Lasts are extremely important for shoe making.Perfectly fitting shoes can only be made with the use of a perfect last. By taking into account the balls of the foot, heels, and instep,as well as how heel height changes the rolling motion of the foot, lasts determine the fit of the completed shoe.

After studying the growth and development of children's feet,Woolly kids took thirty or more different measurements to create a bespoke shoe last. We use the most standard measurements,including: tread, flare, toe spring, throat opening, hell-to-ball,and four separate girth measurements (ball, waist, instep, and heel. After a last has been carved or otherwise created, the shoemakers of Woolly kids use it to attach the separately crafted uppers to the welt and sole. The upper and the sole then form around the last, making a perfectly fitting cavity for the children's foot

Enhanced Durability with Hot Melt Shaping Technology

Woolly Kids utilizes hot-melt adhesives in their footwear manufacturing to enhance durability and productivity. These adhesives offer excellent impact resistance and efficient production capabilities. The specially formulated hot-melt shaping technology plays a vital role in the production of children's snow boots by securely bonding the heel and providing long-lasting structural stability. This technique prevents shoe deformation and promotes proper foot development in infants.

By integrating hot-melt adhesive technology, Woolly Kids ensures their footwear collections, including traditional shoes, outdoor walking sandals, and functional sneakers, meet high standards of durability. Additionally, this approach addresses environmental concerns, providing an all-encompassing solution for the footwear and leather industry.

Stringent Quality Checks

Ensuring Excellence Every Step of the Way

After each pair of woolly children is manufactured, they will undergo two careful inspections. The first inspection takes place at the factory before they are transferred to the storage warehouse. The second inspection occurs when the shoes are packaged and ready for delivery, just before they leave the warehouse. Additionally, we will regularly select shoes from inventory for spot checks. These checks are conducted to ensure that the storage conditions maintain the authenticity of the leather properties and to identify any potential oversights from previous inspections.

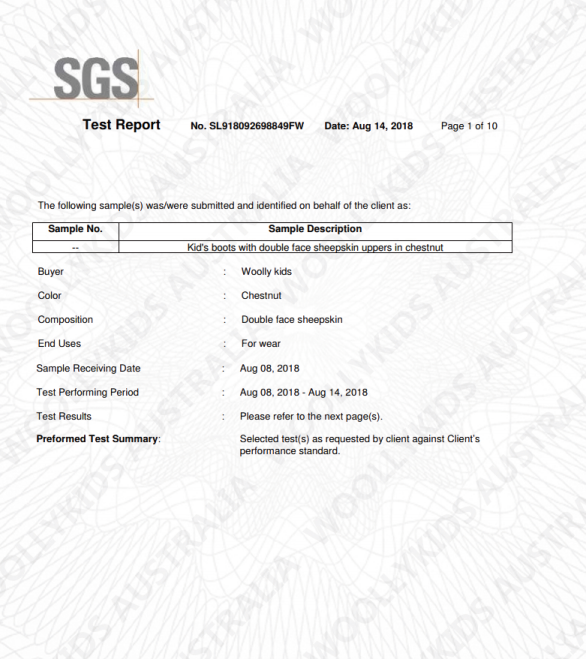

Certified for Quality: Authoritative Verificationd

All the leather we utilize has undergone rigorous testing by SGS, a renowned and authoritative third-party multinational company specializing in product quality control and technical appraisal. The testing process ensures that the leather meets our high standards. We are proud to announce that all quality details have been certified as "PASS," indicating that the leather surpasses the required benchmarks. Furthermore, the testing conducted by SGS has confirmed that there are no detectable heavy metal elements present in our leather materials.

Ethical Manufacturing Practices

Our Commitment to Responsibility

We place a strong emphasis on the social responsibility of our company and prioritize working with manufacturers who share our commitment to upholding human rights. This ensures that our production processes align with ethical standards.

Additionally, we hold ourselves accountable for the well-being and development of children. We understand that the initial steps taken by every young explorer are vital, which is why we are dedicated to providing products that prioritize the safety and comfort of children. Parents can trust us to safeguard their children and have confidence in choosing our brand.